Eagle-Rx

The Eagle-Rx is a high-performance blister packaging machine that was designed to meet Pharmaceutical needs. This machine can be operated by a single person and there is no formal training required. With its recipe driven, toolless changeovers the Eagle-Rx is ideal for changing between multiple products with varying batch sizes. Servo technology ensures repeatability and minimizes mechanical adjustments. The Eagle-Rx’s balcony design achieves a small footprint; perfect for any size cleanroom.

Eagle-Omni

The Eagle-Omni machine was designed to grow with your company. Its small footprint allows for versatile feeding solutions and other various options that can be integrated prior to qualification or as your company grows. The Eagle-Omni features deep cavities and is designed to allow manual or fully automated operation. Quick production changeover is achieved by a recipe driven format and toolless changeovers. The Eagle-Omni can meet all packaging regulations for Medical Devices, Consumer Products, and Cannabis making this the perfect packaging solution.

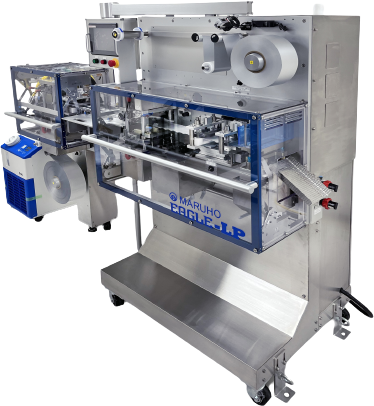

Eagle-Pro

The Eagle-Pro blister packaging machine is ideal for productions of small-lot orders with multiple products. Thanks to platen forming, the change between CPP and PVC is just a matter of exchanging format parts. Format parts are lightweight and can be changed quickly. The main body is lightweight and can be easily moved depending on the necessity. The compact design saves space and the stainless steel full-face guard guarantees a safer operation. also offer a higher speed option with the slightly larger Eagle-ProS

Eagle-Uni Thermoformer

The semi-automatic, multi-functional Eagle-Uni blister packaging machines are ideal for packaging development, small scale production, material testing, and more. The universal station can perform the forming, sealing, and punching functions in consecutive steps. The machine can be used to package solids, powders, liquids, or devices.