Performance you want and the precision you need.

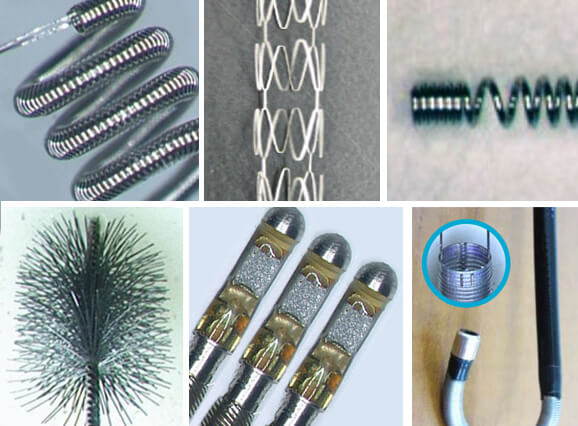

The medical device industry often requires high performance and dependable precision to meet packaging regulations. As a subsidiary of a pharmaceutical company we also have sister companies that specialize in the creation of medical devices. We understand your needs and wants. We specialize in providing custom turnkey solutions for feeding and can integrate with many end of line (EOL) equipment to help meet your packaging needs.

MHI’s mission is to meet our customers’ needs by providing:

- The highest possible quality blister packaging equipment

- Unparalleled ease-of-use including simple set-up and run procedures, simple rapid tooling changeovers, and easy to understand manuals

- Technical service, tooling, and integration services locally in North America

- Exceptional value with economical pricing

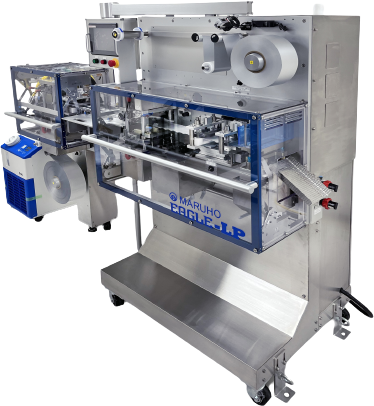

The Eagle-Omni machine was built for the company that needs a machine to grow as they do. This machine features deep cavities and is designed to allow manual or fully automated operation. Quick production changeover is achieved by a recipe driven format and toolless changeovers. The Eagle-Omni really separates itself from other machines with its small footprint and versatile feeding solutions. The perfect packaging machines for your medical device needs.

Download our brochure and reach out today!